How to Wind a Mechanical Clock

A Complete Guide to Proper Winding, Frequency, and Safety

Mechanical clocks require regular winding to maintain consistent operation and accurate timekeeping. While winding is a routine task, improper technique can damage internal components, cause uneven power delivery, or lead to premature wear. This guide explains how mechanical clocks are wound, how often they should be wound, and how to do so safely and correctly.

Understanding Why Clocks Need Winding

Mechanical clocks are powered by either weights or mainsprings. In both cases, winding stores potential energy that is gradually released to drive the gear train, escapement, and regulating system.

Spring-driven clocks store energy by tightening a coiled steel spring inside a barrel. As the spring unwinds, it delivers torque to the movement. Weight-driven clocks store energy by lifting weights, which then descend slowly under gravity.

Consistent winding ensures even power delivery, stable amplitude at the escapement, and reliable timekeeping.

Identifying Your Clock’s Winding System

Before winding, it is essential to determine which type of winding system your clock uses.

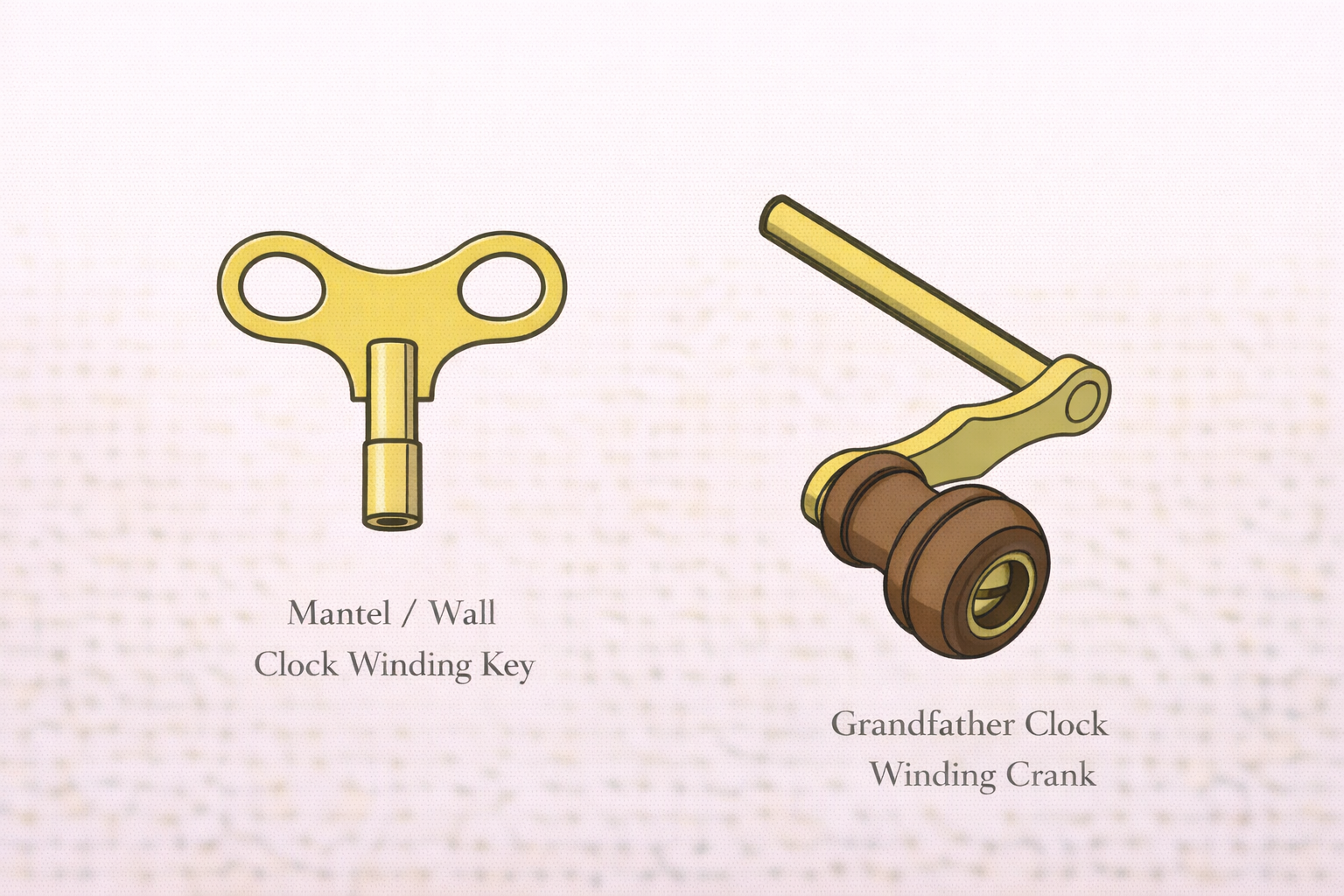

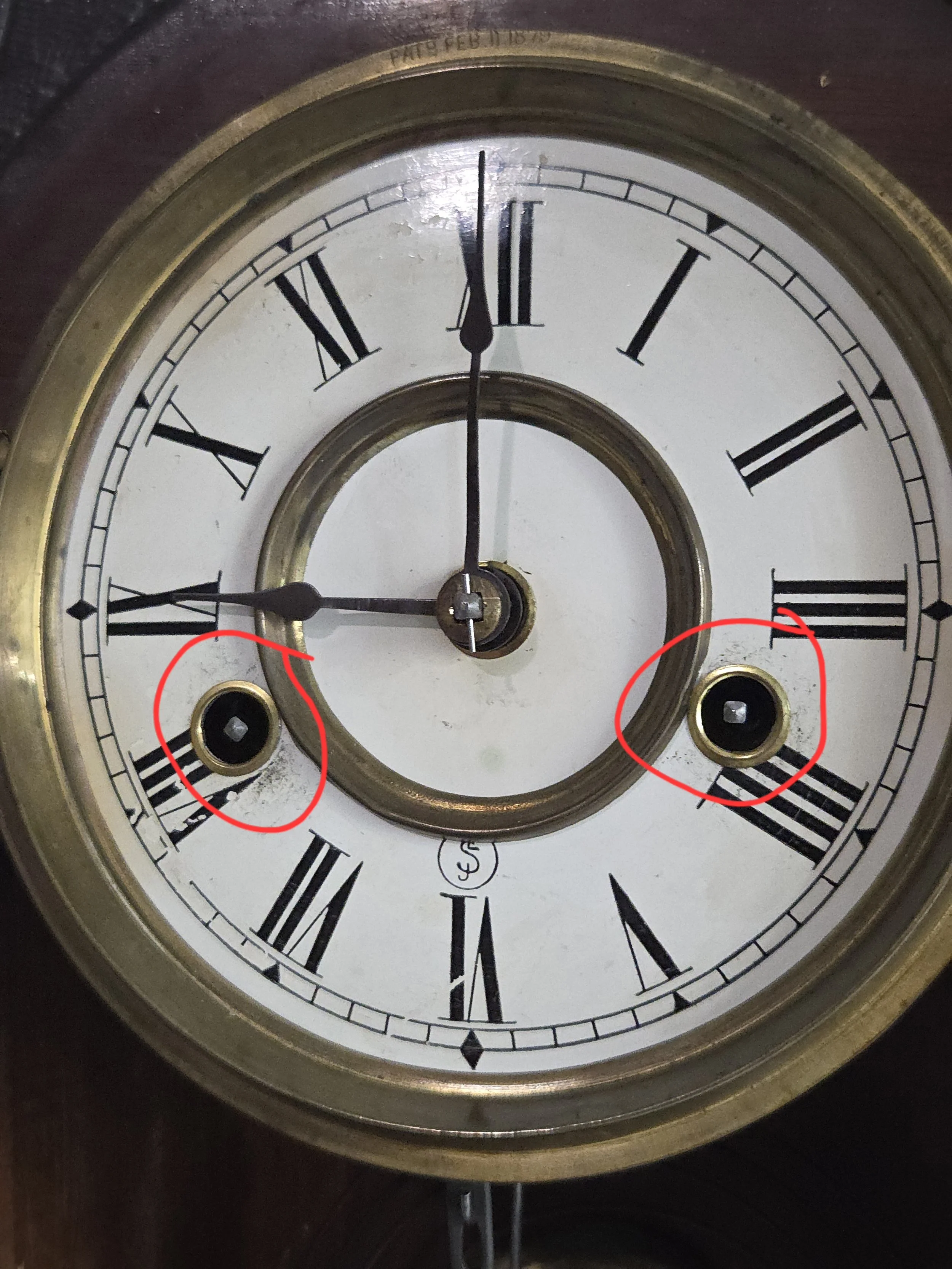

Many wall clocks, mantel clocks, and bracket clocks are spring-driven and are wound using a removable clock key inserted into winding arbors on the dial. These clocks may have one, two, or three winding points depending on whether they drive time only, time and strike, or time, strike, and chime.

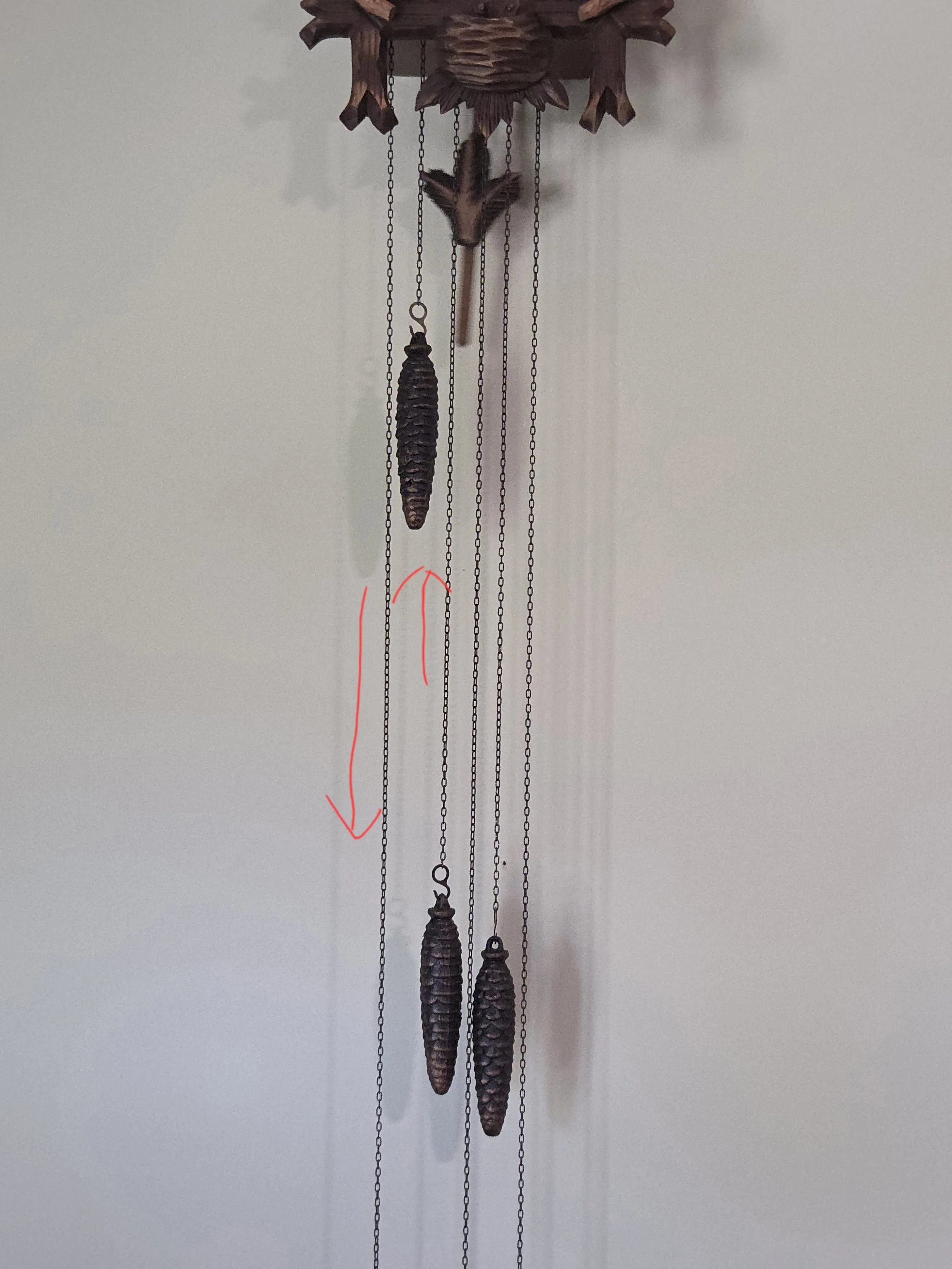

Weight-driven clocks, such as tall case (grandfather) clocks and some wall regulators, are wound by lifting the weights, either manually or via a chain or cable system.

Never attempt to wind a clock without first confirming the correct method.

How Often a Clock Should Be Wound

Most mechanical clocks are designed to run for a specific duration between windings.

Eight-day clocks should be wound once every seven days. Winding slightly before the clock runs down ensures consistent power delivery and helps maintain accuracy.

Thirty-hour clocks should be wound daily.

Thirty-one day clocks should be wound once every month.

Weight-driven clocks should be wound when the weights approach the lower third of their travel, rather than allowing them to reach the bottom.

Winding on a regular schedule, ideally the same day and time each week, promotes stable performance.

Proper Technique for Winding a Spring-Driven Clock

When winding a spring-driven clock, insert the correct clock key fully onto the winding arbor. The key should fit snugly without wobble. Using an incorrect key can round the arbor or crack the dial.

Turn the key slowly and steadily, applying smooth pressure. Clocks may wind in a clockwise direction or counterclockwise direction, it depends on the direction the spring is mounted on the arbor; gently test both directions and you should be able to feel which way the spring winds. If resistance increases significantly, stop turning. A fully wound spring will not accept further rotation.

Never force the key past resistance. Overwinding is not possible in a healthy movement, but forcing a bound or fully wound spring can break internal components.

Wind each arbor completely before moving to the next, especially on chiming clocks.

Proper Technique for Winding a Weight-Driven Clock

For chain-driven clocks, pull the free end of the chain downward to raise the weight on the opposite side. Pull evenly and avoid jerking motions.

For cable-driven clocks, use the crank or key to raise the weight slowly. Ensure the cable winds evenly on the drum and does not overlap or twist.

Never lift weights by hand unless the clock is specifically designed for manual lifting. Always use the chain or winding mechanism provided.

Winding Order for Multi-Train Clocks

Clocks with multiple trains should be wound in a consistent order to avoid confusion.

A typical three-train clock has:

A time train

A strike train

A chime train

Winding order does not affect function, but developing a habit, such as left to right or center first, helps ensure no arbor is missed.

What to Expect After Winding

After winding, the clock should resume normal operation immediately. Chiming clocks may chime shortly after winding if the chime train was near activation.

It is normal for a clock to run slightly differently immediately after winding due to increased power. This typically stabilizes within several hours.

If the clock fails to run after winding, stops shortly afterward, or produces unusual noises, further inspection or professional service may be required.

Common Winding Mistakes to Avoid

Forcing the winding key after resistance is felt can damage the mainspring or winding arbor.

Using pliers or makeshift tools instead of a proper clock key can permanently damage the movement.

Allowing a clock to run completely down regularly can cause uneven wear and reduce timekeeping stability.

Failing to support chains or cables during winding can result in tangles or derailment.

Safety and Handling Notes

Always wind clocks gently and deliberately. Mechanical movements are precise instruments, not high-torque mechanisms.

If a clock resists winding strongly before it appears fully wound, stop and investigate. Hardened lubricant, broken springs, or internal damage may be present.

When in doubt, do not force the mechanism.