Balance Wheel Regulation

Balance wheel regulation is used on clocks that do not rely on a pendulum for timekeeping. Instead, these clocks regulate speed through a spring-driven balance wheel and escapement assembly, commonly referred to as a platform escapement or balance unit. This system allows the clock to operate reliably regardless of orientation and makes it suitable for portable, shelf, and mantel clocks.

Balance-regulated clocks are common in carriage clocks, tambour mantel clocks, and many wall clocks produced in the late 19th and early 20th centuries.

Identifying Balance Wheel–Regulated Clocks

Clocks regulated by a balance wheel typically share the following characteristics:

No pendulum or visible pendulum leader

A compact escapement assembly mounted on top or rear of the movement

A balance wheel that oscillates rapidly back and forth

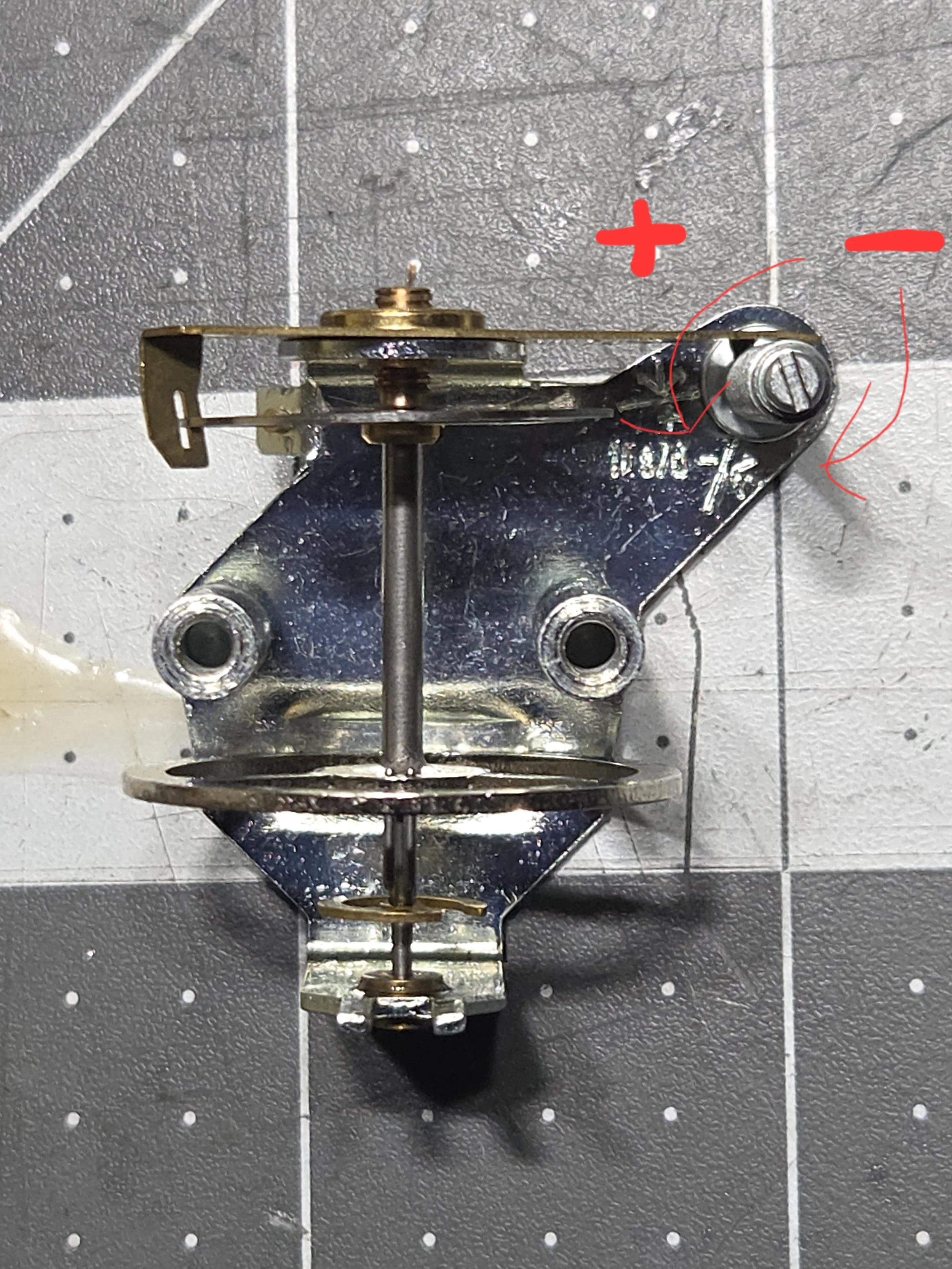

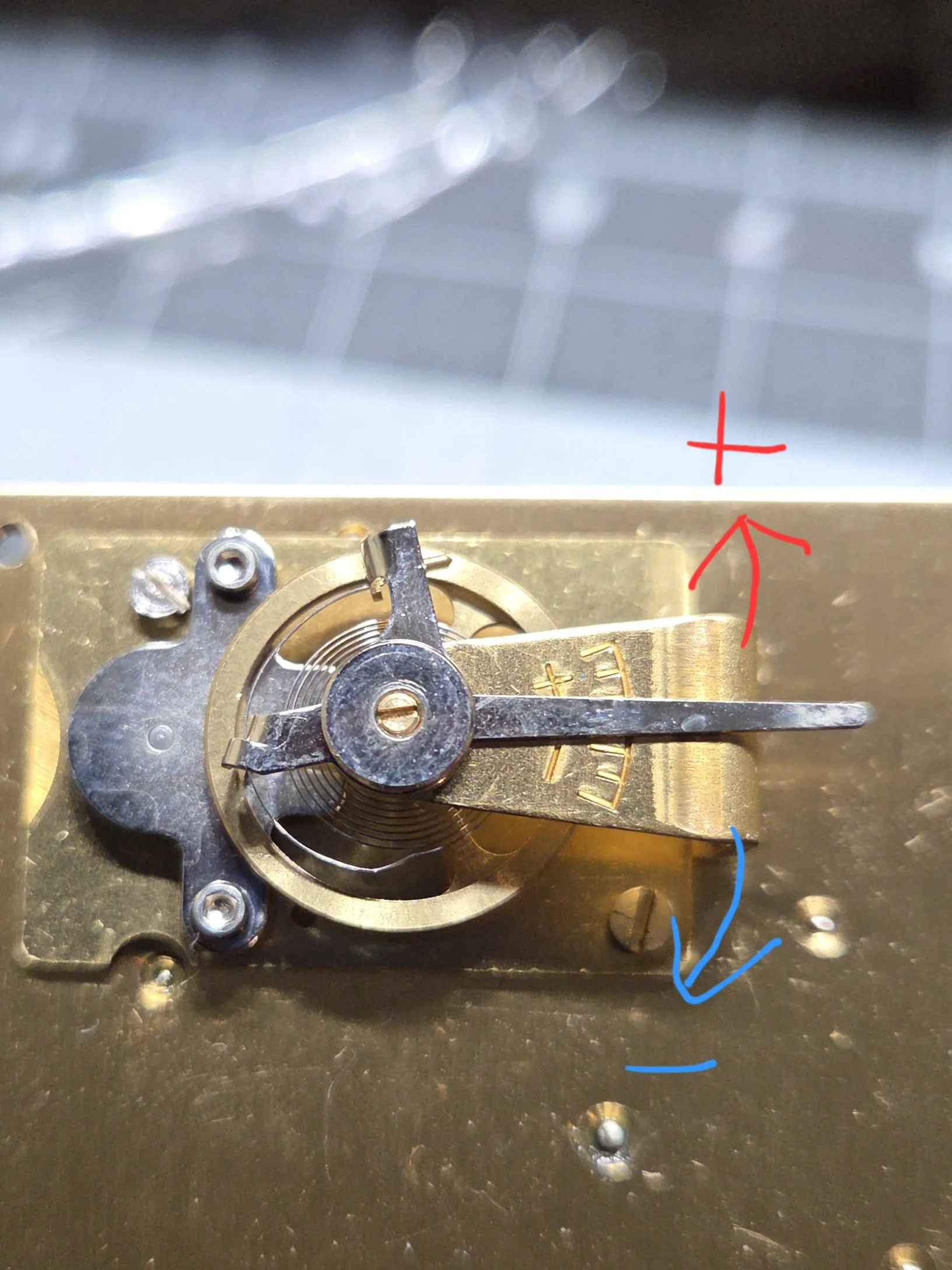

A regulator lever or fine adjustment screw marked F / S, Fast / Slow, or + / –

Unlike pendulum clocks, these clocks are not affected by case height and require no vertical clearance for operation.

Placement & Stability

Although balance wheel clocks are less sensitive than pendulum clocks, proper placement still affects performance.

Place the clock on a firm, level surface

Avoid vibration from nearby appliances or foot traffic

Keep away from strong magnetic fields and heat sources

Ensure the case sits flat and does not rock

Balance wheel clocks do not require beat adjustment in the traditional pendulum sense, but excessive tilt can still affect timekeeping.

Understanding Balance Wheel Regulation

Timekeeping speed is controlled by the effective oscillation rate of the balance wheel. Regulation is achieved by altering the balance’s restoring force or inertia through a regulator lever or screw.

General principles:

Increasing the balance rate causes the clock to run faster

Decreasing the balance rate causes the clock to run slower

Adjustments should always be small and deliberate.

Step-by-Step Regulation Procedure

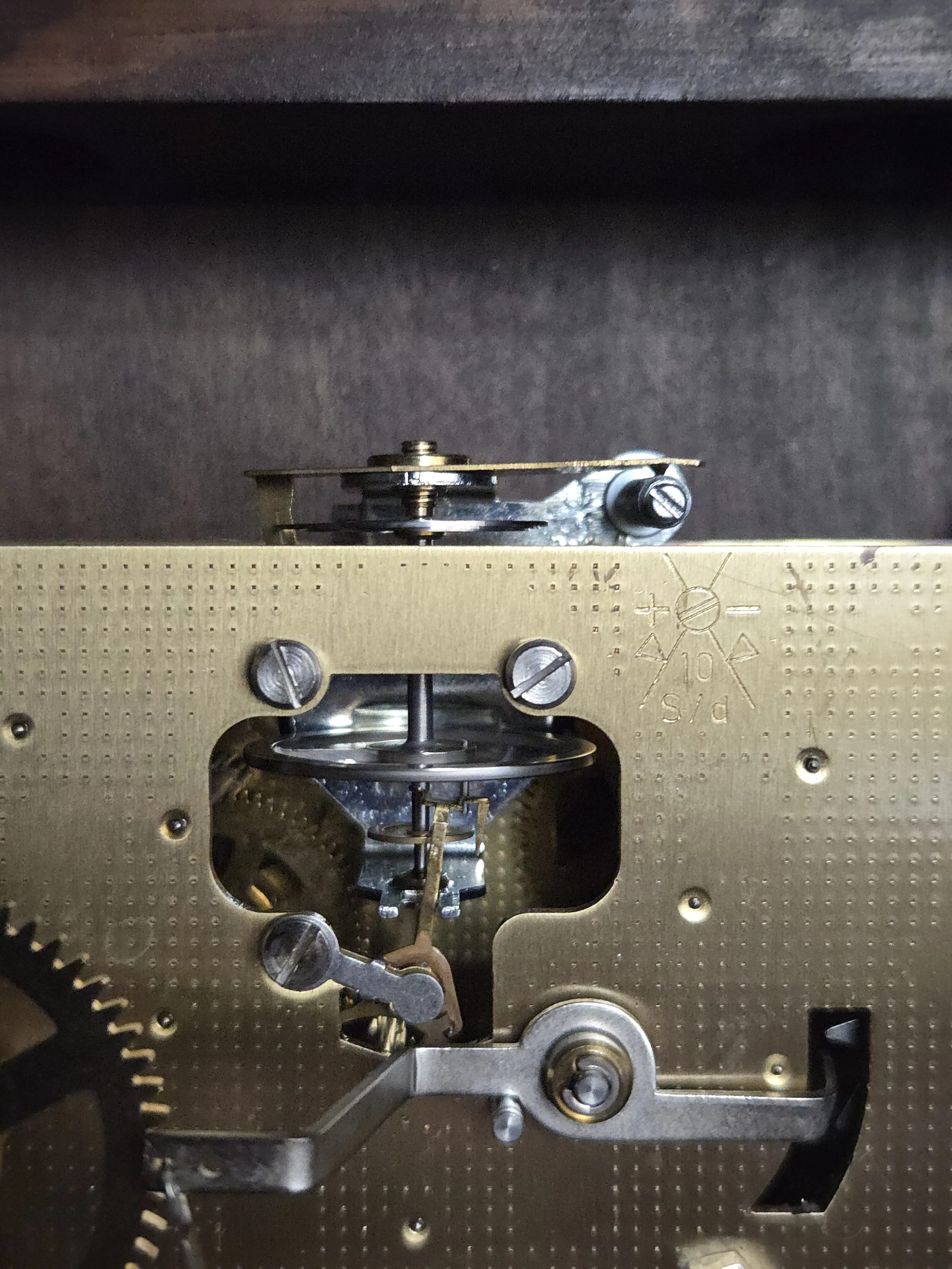

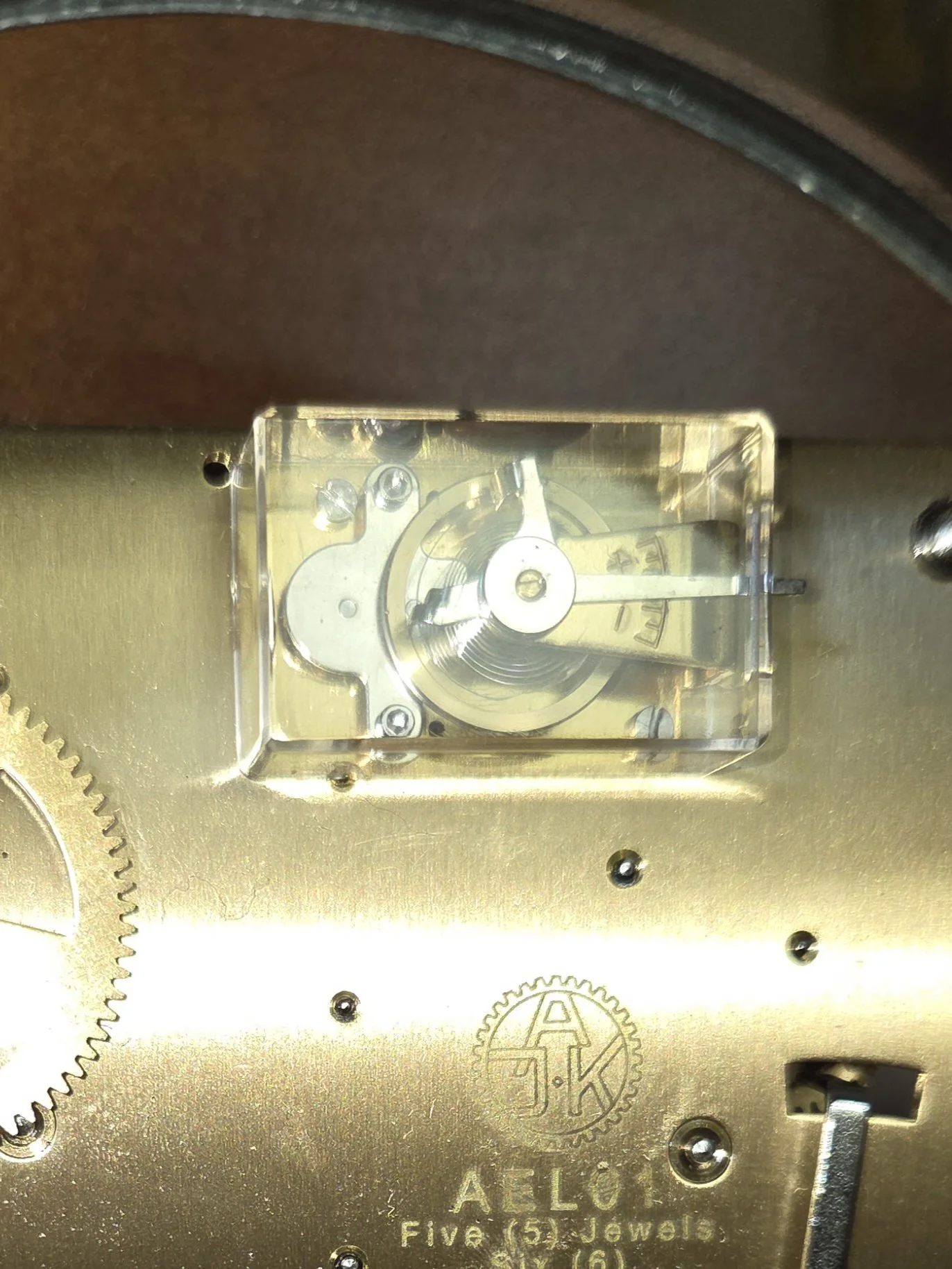

Step 1: Locating the Regulator

The regulator is typically found:

On the balance platform itself

Accessible from the rear of the movement

Sometimes visible through a top or rear glass panel

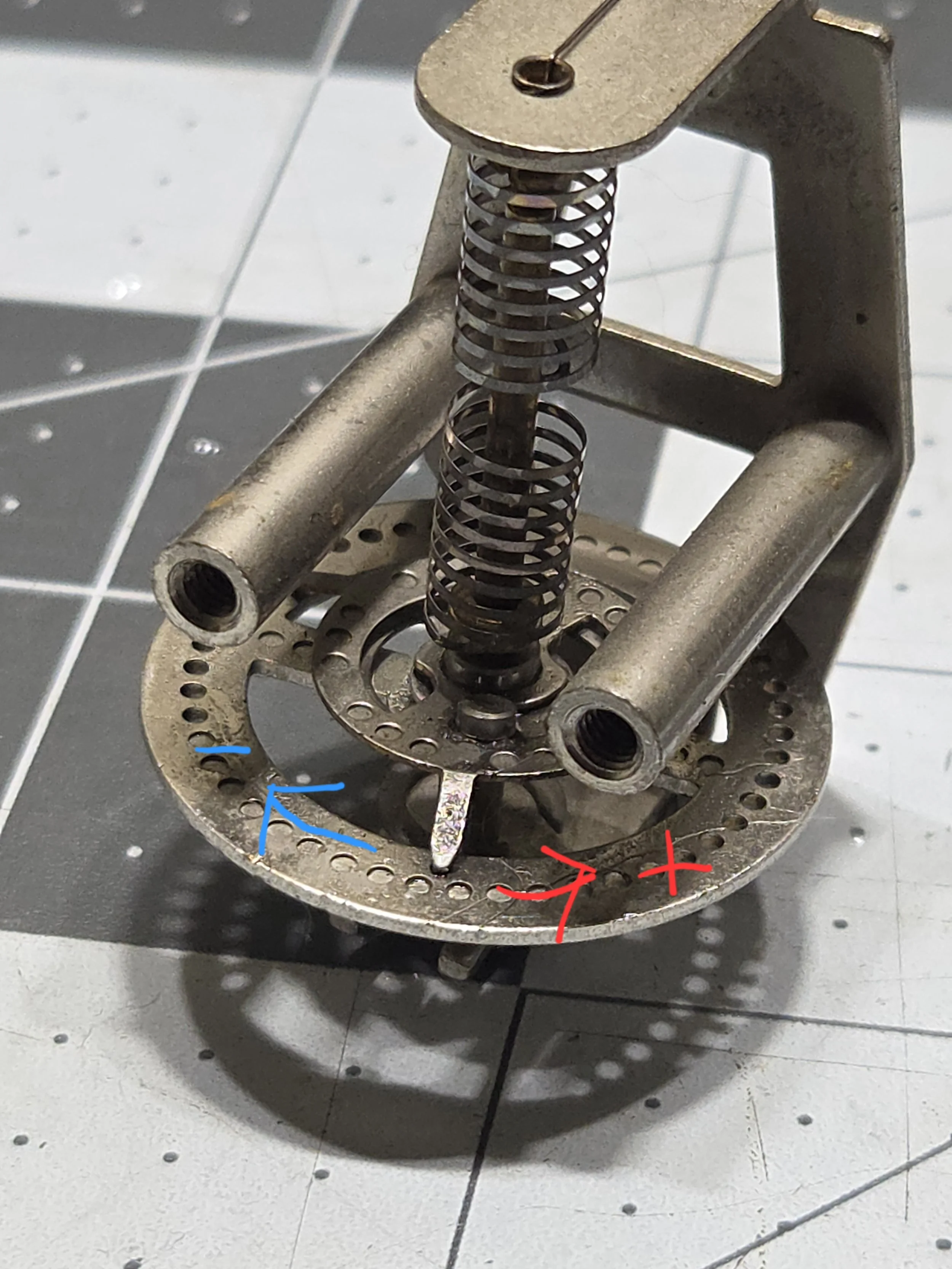

Common regulator types include:

Sliding regulator levers

Micrometer screws

Index arms acting on the balance spring

Look for markings such as F / S, Fast / Slow, or + / –.

Step 2: Adjustment Direction

Regulator markings indicate direction, but the following rules generally apply:

Moving the regulator toward Fast increases the rate

Moving the regulator toward Slow decreases the rate

Clockwise or counterclockwise rotation depends on the regulator design

Always observe the markings on the movement rather than assuming direction.

Step 3: Making Adjustments

Proper regulation requires restraint.

Move the regulator in very small increments

Typical adjustment is equivalent to 1–2 mm of lever travel or a fraction of a screw turn

Never move the regulator from one extreme to the other

After each adjustment:

Allow the clock to run for at least 24 hours

Compare against a known accurate time source

Multiple small corrections are safer than one large change.

Step 4: Avoiding Over-Adjustment

Over-adjustment is the most common mistake.

Signs of over-adjustment include:

Clock gaining or losing several minutes per day

Inconsistent timekeeping

Uneven or erratic balance motion

If over-adjusted:

Return the regulator closer to its original position

Resume adjustments in smaller increments

Balance wheel systems are sensitive and respond quickly to changes.

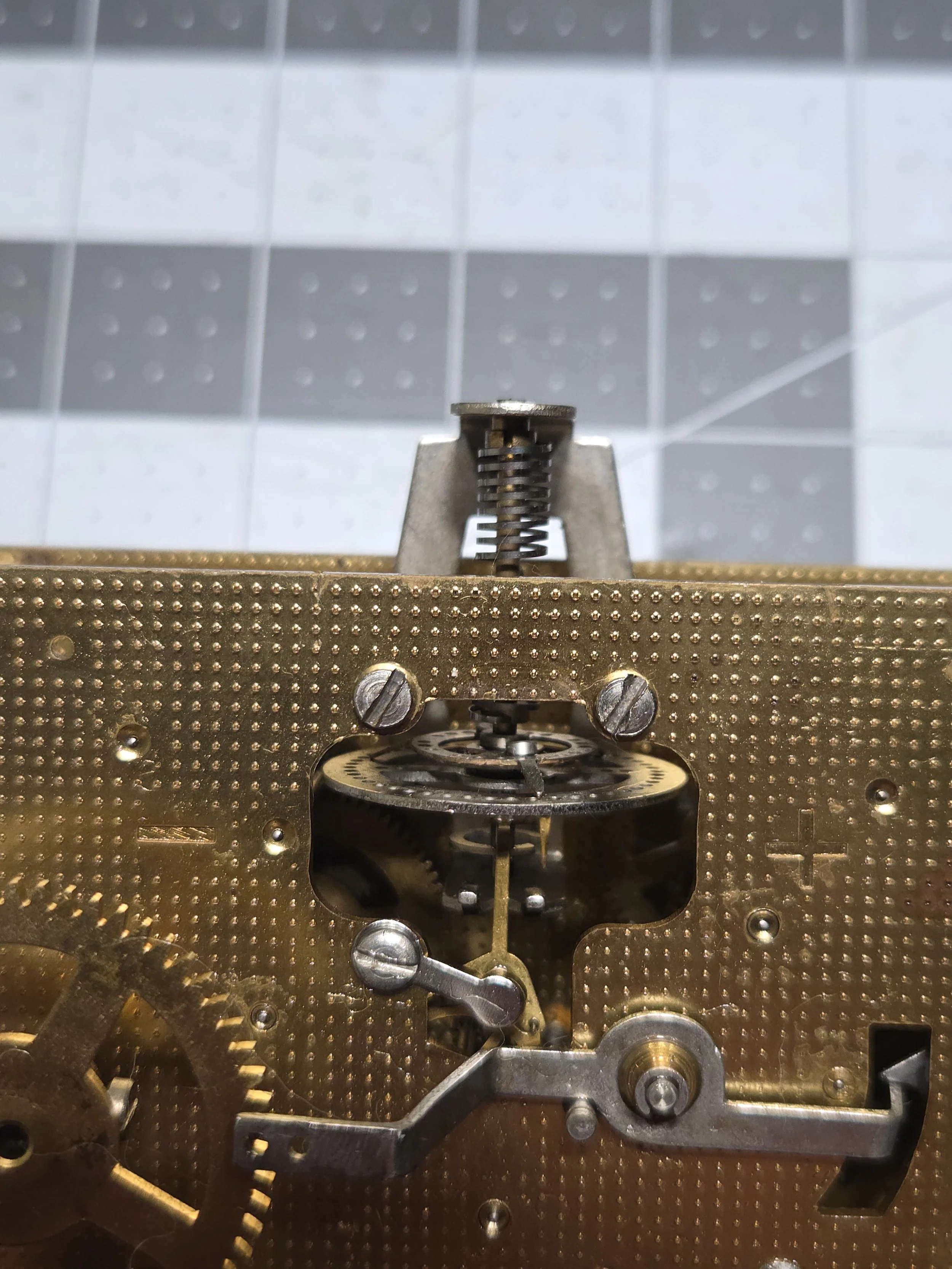

Step 5: Observing Proper Balance Wheel Operation

A properly operating balance wheel should:

Oscillate evenly side to side

Move freely without contacting surrounding parts

Return consistently to center

If the balance wheel:

Hesitates

Rubs or binds

Stops intermittently

Regulation alone will not correct the issue, and mechanical service may be required.

Maintenance Notes

Never oil the balance wheel or balance spring yourself

Do not attempt to bend or reshape the balance spring

Professional servicing is recommended every 5–10 years

The balance assembly is one of the most delicate components in any clock.

When to Stop & Call a Technician

Stop regulating and consult a technician if:

The clock will not respond to regulator adjustments

The regulator is already near its Fast or Slow limit

The clock gains or loses time erratically

The balance wheel hesitates, rubs, or stops intermittently

These conditions typically indicate mechanical wear, contamination, or balance assembly issues rather than a regulation problem.